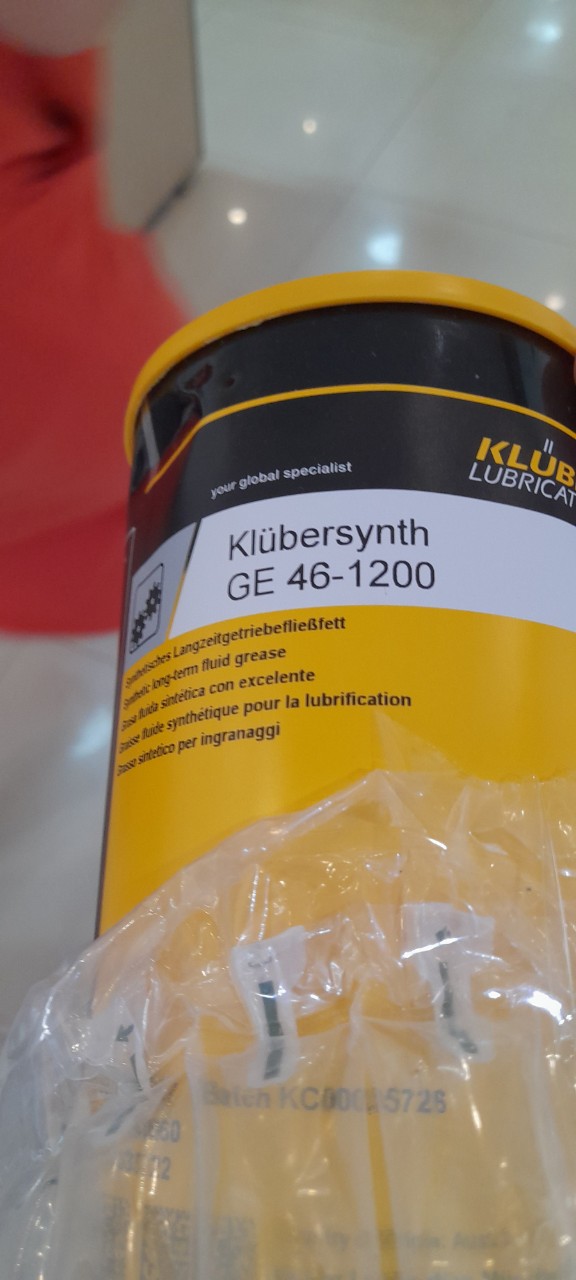

Synthetic long-term fluid grease with excellent anticorrosive effect.

I. Description of Klubersynth GE 46-1200

- Small gear systems demand high efficiency and a lubricant with a wide temperature range along with a long service life.

- Our fully synthetic long-term fluid gear grease Klübersynth GE 46-1200 based on a polyglycol base oil and a lithium soap thickener was especially developed to meet the tough requirements of advanced small gears.

- The combination of base oil and additives offers optimised wear protection under mixed friction and good pressure absorption capacity in the lubrication of gears. Klübersynth GE 46-1200 also offers excellent corrosion protection and good compatibility with sealing elastomers.

- The consistency of this fluid grease has been tuned to enable excellent backflow and hence a constant supply to the friction point.

- Please do not hesitate to contact our experts regarding the demands in your own application.

II. Your benefits at a glance of Klubersynth GE 46-1200

- Reliable lubricant film formation in a wide service temperature range

- Good wear protection and high pressure absorption capacity

- Optimised friction behaviour leading to higher efficiency

- Good seal life due to excellent compatibility

- Excellent backflow to the friction point

- Excellent ageing and oxidation resistance for long service life

III. Application of Klubersynth GE 46-1200:

- We developed Klübersynth GE 46-1200 on the basis of our long experience in the lubrication of spur, bevel and worm gears.

Especially for steel/steel combinations, for example in small and miniature gears, gear motors and power tool gears, Klübersynth GE 46-1200 offers outstanding performance characteristics. - Medium peripheral speeds of 4-5 m/s can be effectively handled by this grease. It also provides vibration and noise damping.

- Klübersynth GE 46-1200 can also be used to optimise the lubrication of ball and roller guides, plain and rolling bearings, and toothed couplings from – 30 to 120 °C. It may even be applied at extreme temperatures down to -50 °C since Klübersynth GE 46-1200 will build up a load-carrying lubricant film at these low temperature conditions.

Application notes:

- We developed Klübersynth GE 46-1200 on the basis of our long experience in the lubrication of spur, bevel and worm gears.

Especially for steel/steel combinations, for example in small and miniature gears, gear motors and power tool gears, Klübersynth GE 46-1200 offers outstanding performance characteristics. - Medium peripheral speeds of 4-5 m/s can be effectively handled by this grease. It also provides vibration and noise damping.

- Klübersynth GE 46-1200 can also be used to optimise the lubrication of ball and roller guides, plain and rolling bearings, and toothed couplings from – 30 to 120 °C.

Product data:

| Article number | 027035 |

| NLGI grade, DIN 51818 | 00 |

| Color space | brown |

| Texture | homogeneous |

| Density at 20 °C | approx. 0.99 g/cm³ |

| Worked penetration, DIN ISO 2137, 25 °C, lower limit value | 400 x 0.1 mm |

| Worked penetration, DIN ISO 2137, 25 °C, upper limit value | 430 x 0.1 mm |

| Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C | approx. 120 mm²/s |

| Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C | approx. 20 mm²/s |

| Shear viscosity at 25 °C, shear rate 300 s-1; equipment:rotational viscometer | <= 2 000 mPas |

| Copper corrosion, DIN 51811, (lubricating grease), 24h/100°C | 1 – 100 corrosion degree |

| FZG scuffing test, DIN ISO 14635-1, A/8.3/90, change in weight | < 0.2 mg/kWh |

| FZG scuffing test, DIN ISO 14635-1, A/8.3/90, scuffing load stage | > 12 |

| Drop point, DIN ISO 2176, IP 396 | >= 160 °C |

| Minimum shelf life from the date of manufacture – in a dry, frost-free place and in the unopened original container, approx. |

24 months |

Đánh giá

Chưa có đánh giá nào.

Hãy là người đầu tiên nhận xét “Klubersynth GE 46-1200 Mỡ bôi trơn tổng hợp tuổi thọ dài đóng gói 01kg”